Apollo® Ball Valves: The Key to Secure and Efficient Tank Car Operations

Within the tank car industry, ball valves are frequently employed to control the flow of liquids or gases in and out of the tank. These valves are typically installed at the bottom outlets or on the top of the tank for filling or emptying operations. The ball valve's design allows for efficient and reliable control of the product flow, ensuring proper loading, unloading, and in-transit operations.

Within the tank car industry, ball valves are frequently employed to control the flow of liquids or gases in and out of the tank. These valves are typically installed at the bottom outlets or on the top of the tank for filling or emptying operations. The ball valve's design allows for efficient and reliable control of the product flow, ensuring proper loading, unloading, and in-transit operations.

Here are a few reasons why ball valves are preferred on tank cars:

Quick and reliable operation: Ball valves have a quarter-turn operation, meaning they can be fully opened or closed with just a 90-degree rotation. This allows for faster response times, which is crucial in controlling the flow of fluids or gases in freight train applications.

Durability: Freight trains operate in demanding environments with constant vibration, changes in pressure, and exposure to various weather conditions. Ball valves are known for their robust construction and ability to withstand such harsh conditions without significant wear or failure.

Minimal leakage: Ball valves provide a tight seal when closed, minimizing the risk of leakage. This is especially important in freight train applications, as any fluid or gas leaks can be hazardous and may lead to safety issues or operational inefficiencies.

Ease of maintenance: Ball valves are relatively simple in design, consisting of fewer moving parts compared to other valve types. This simplicity makes them easier to maintain and repair. When maintenance or servicing is required, the ball valve can be quickly disassembled, allowing for efficient inspection, cleaning, and replacement of components if necessary.

Cost-effectiveness: Considering their long lifespan, durability, and ease of maintenance, ball valves offer a cost-effective solution for freight train operations. While they may have a higher upfront cost compared to some other valve types, their extended service life and reduced maintenance needs often make them more economical in the long run.

These characteristics are essential for maintaining the integrity and safety of the transported commodities and preventing any accidents or environmental hazards during rail transportation.

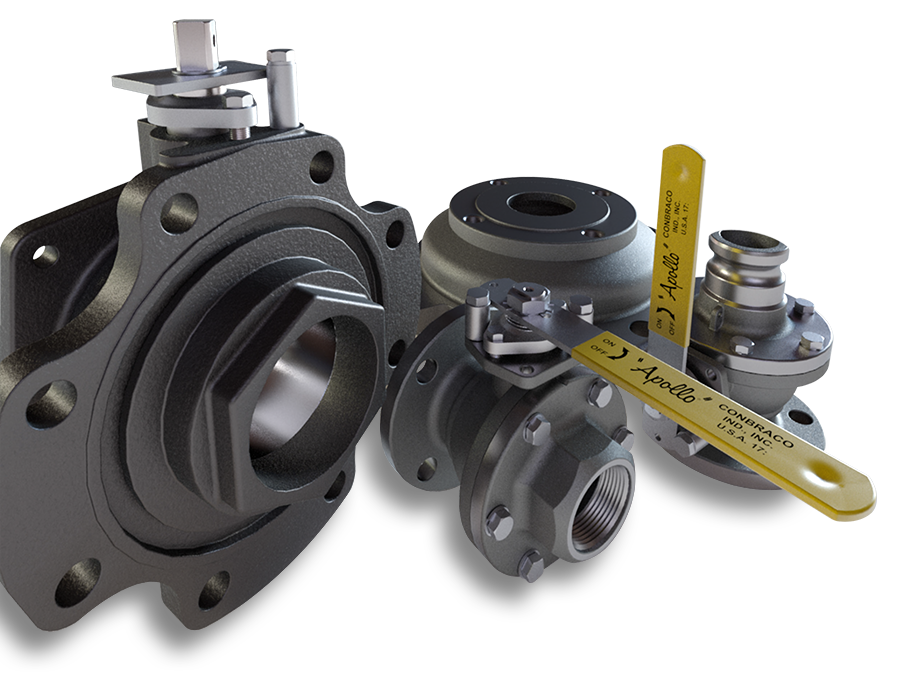

Apollo® is the brand of ball valves made in the U.S. with the best delivery times in the industry. Manufactured in ISO-registered and AAR-certified facilities means never having to compromise on performance or reliability. Designed and built in Aalberts integrated piping systems ISO-9001 registered U.S. facilities, these valves feature corrosion-resistant bodies and internal components that offer extended service life. They are manufactured to stringent specs and approved by the Association of American Railroads(AAR).

As the exclusive distributor of Apollo® valves for the transportation industry, Salco Products Inc has many different arrangements, materials, and sizes in stock for immediate shipment.