Service Center

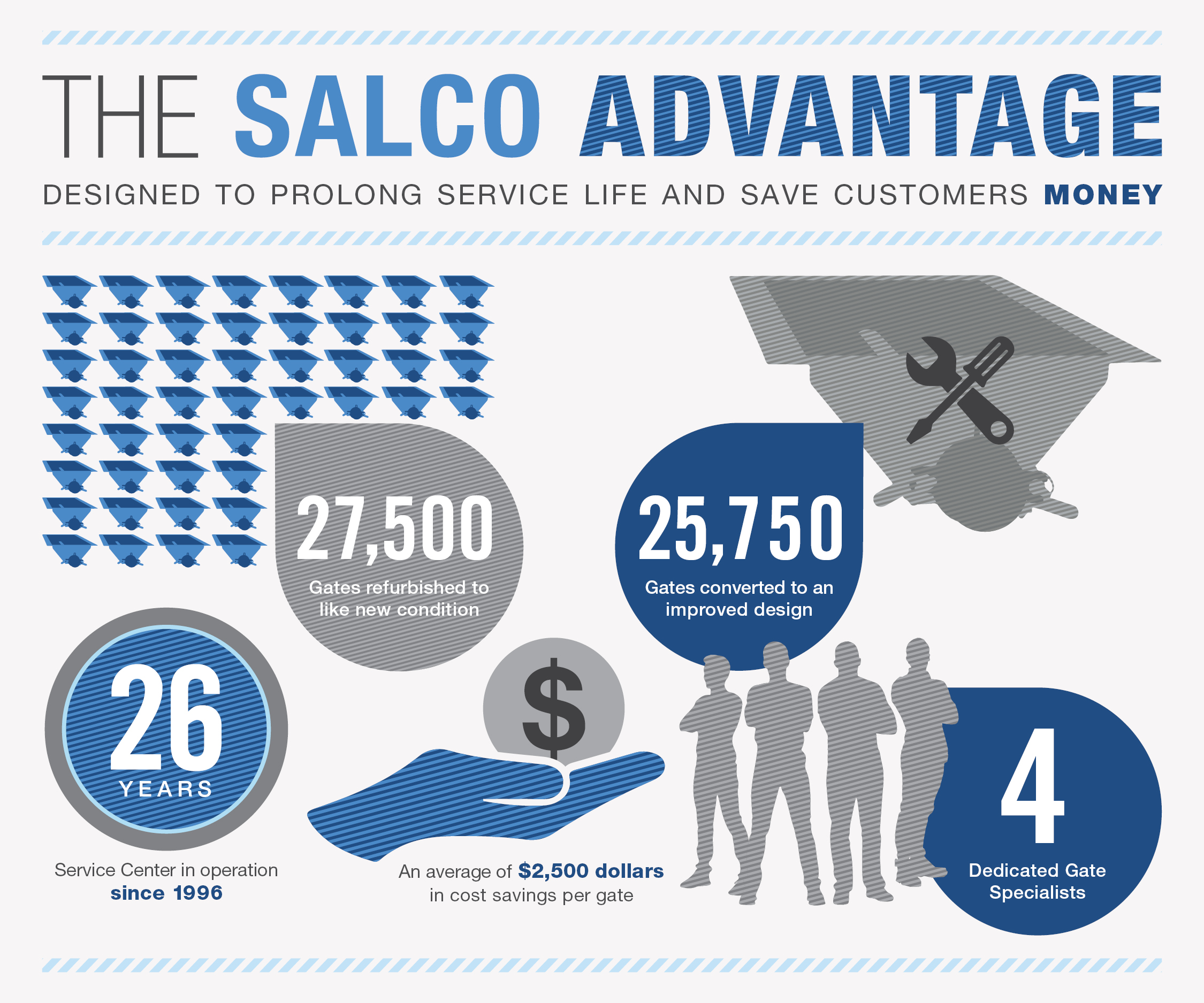

Salco Products’ Service Center located in Houston, TX, repairs, reconditions and performs upgrades to hopper car outlet gates. With certified welders that meet AAR requirements, Salco’s Service Center saves our customers thousands of dollars each year by helping them avoid the purchase of new gates.

A full reconditioning includes inspection, disassembly, repair of required items, glass bead blast, rinse, buffing and finally reassembly with new gaskets and hardware. Not only does Salco design upgrades and improvements to problematic gates, but also designs custom modifications based on specific customer needs.

Gate Repair/Reconditioning

Salco provides a comprehensive 6-Step repair & reconditioning process for all types of outlet gates.

Our welders are certified and meet AAR MSRP C-II M1001 (freight car design, fabrication and construction) which states that all welding will be in accordance with the AWS D.15 and specifically D.15.1 that governs all welds on railcars.

| Outlet Gates Undergo Six Step Process |

| 1. Inspection |

|

| A thorough inspection of gate to determine degree of repair and reconditioning required. |

| 2. Disassemble |

|

| Gate is totally dismantled prior to initiating required repairs and reconditioning. |

| 3. Blasted |

|

| Glass bead blasting and power washing with hot water removes surface grease and grime. |

| 4. Buffed |

|

| Thorough buffing and cleaning removes any remaining debris and surface scratches. |

| 5. Reassemble / Inspection #2 |

|

| After thorough inspection to ensure quality, the gate is reassembled using new nuts, bolts, washers, gaskets and caps. |

| 6. Delivered |

|

| Repaired, refinished, reassembled, fully inspected, approved for resale, and ready for delivery. |

Gate Conversion

Salco’s Service Center also offers complete outlet gate conversion services.

During conversion process gates are completely disassembled, cleaned, buffed and fitted with new gaskets.

Some Popular Conversions Offered

During conversion process gates are completely disassembled, cleaned, buffed and fitted with new gaskets.

Some Popular Conversions Offered

ACF 5135 & 5235 Outlet Gate Conversion

Conversion includes welding shut gap, helping to eliminate entrapment and product contamination.

Micro-Matic to Kam-Op Conversion

Salco's "Kam-Op" conversion eliminates "jumping time". Kam design replaces loop braket/rack and pinion. New extended handles prevent "pinch points".

ACF 5131 to 4590-CV Conversion

Salco's 4590-CV conversion eliminates binding/seizing of control valve caused by entrapment. Also eliminates bail assembly preventing "pinch points". Limiter Pin reduces 90 degree handle turn to just 45 degrees.

Conversion includes welding shut gap, helping to eliminate entrapment and product contamination.

Micro-Matic to Kam-Op Conversion

Salco's "Kam-Op" conversion eliminates "jumping time". Kam design replaces loop braket/rack and pinion. New extended handles prevent "pinch points".

ACF 5131 to 4590-CV Conversion

Salco's 4590-CV conversion eliminates binding/seizing of control valve caused by entrapment. Also eliminates bail assembly preventing "pinch points". Limiter Pin reduces 90 degree handle turn to just 45 degrees.

As well as reconditioning outlet gates, Salco’s Service Center also reconditions hatch covers.

Our welders are certified and meet AAR MSRP C-II M1001 (freight car design, fabrication and construction) which states that all welding will be in accordance with the AWS D.15 and specifically D.15.1 that governs all welds on railcars.

![]() It can be seen quality work is always the goal, and the people take pride in what they do."

It can be seen quality work is always the goal, and the people take pride in what they do."

Charles Dillner

Schlumberger PPC