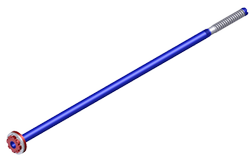

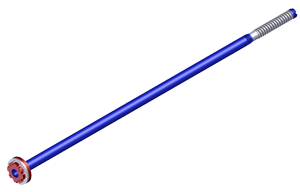

Eduction Tube with Reducing Flange, 4 inch x 3 inch, 3 1/2 inch diameter pipe, 110 inches long

Part #: HS43DT110

UHMWPE, SS and PTFE, 4"x3" 150 lb Flanges, 8x 3/4" Slotted Bolt Holes on a 7 1/2" to 7 3/4" Bolt Circles, 3" Flange Thickness, Ø3 1/2" Outer Diameter x Ø2 1/2" Inner Diameter, 110" Long from the Bottom of the Flange, Flex End for Finished Tube Length of 121" to 127 1/2", Serrated Gasket Surfaces, For Non-Flammable Service Only, Patent No. 8,894,102 B2, AAR Approval # E202144

Key Features

- Seamless construction and maintenance free UHMWPE dip tubes are corrosive resistant for use in the Chlor-Alkali chemical industry.

- Economical, flexible and lightweight; can be easily installed by one worker. Can be cut to fit on location.

- Produced from UHMWPE (UHMWPE) and Teflon®, making tubes six times more abrasive resistant than steel dip tubes.

- Flex end on the tube eliminates the need for saddle/pipe guide.

- Concentric serrations on the flange enables positive sealing of gaskets.

- Available in a variety of sizes, flanges can be constructed to suit any inlet/outlet application. Low profile reducing flanges (strike tubes) also available.

- Kynar® coated flange also available for maximum corrosion resistance.

- Wide Temperature Ranges: Pipes and flanges can withstand temperatures between -300° F and +180° F (-184° C to 82° C)Optional Flex End is FEP (Teflon®) and can withstand temperatures between -300° F and +400° F (-184° C to 204° C